The Next Generation of Force-Controlled Cobots

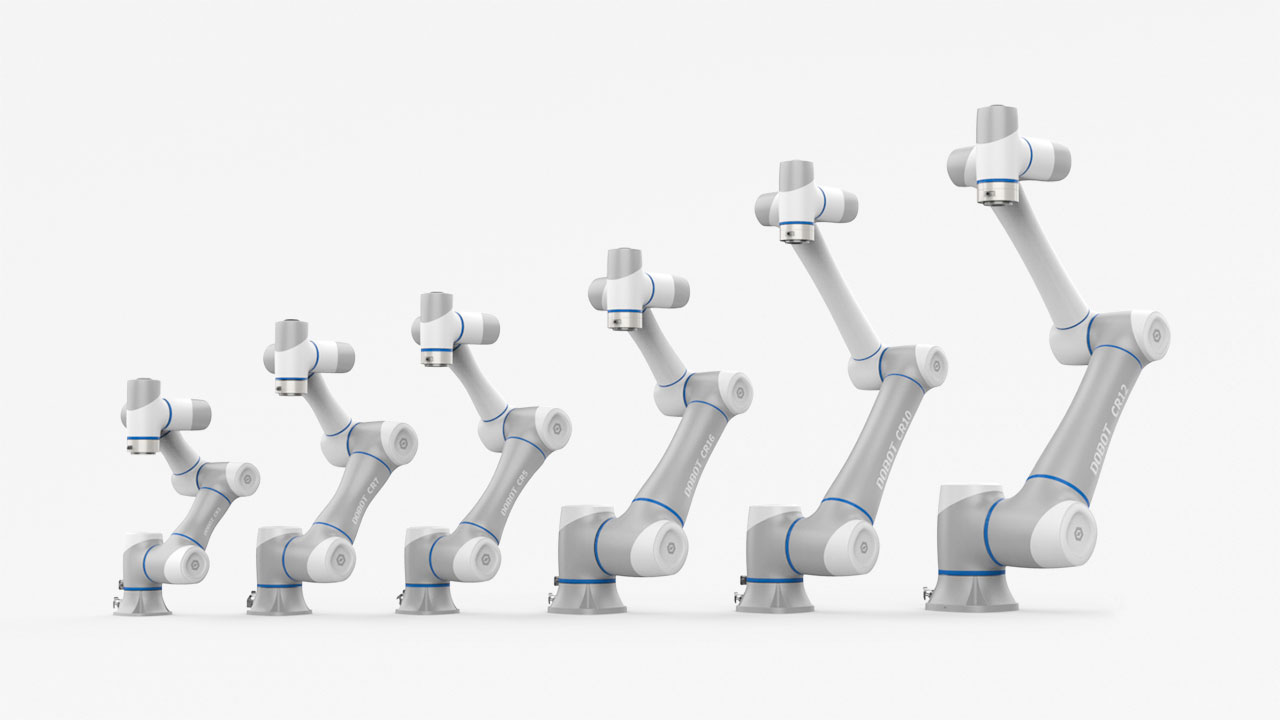

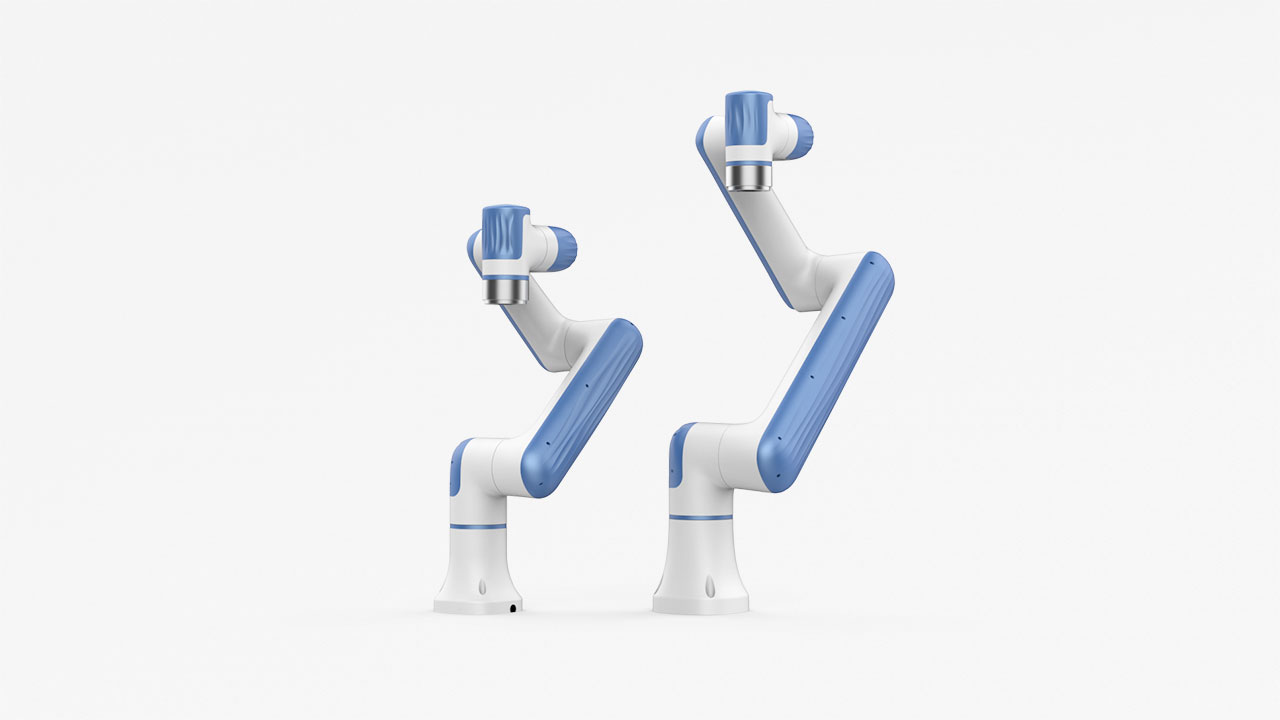

Designed for high-end manufacturing applications like precision assembly, complex grinding, and medical automation, the DOBOT CRAF series redefines intelligent force control with its proprietary algorithms and integrated high-resolution sensors.

Delivering plug-and-play operability without installation or deployment, it enables adaptive force applications and seamless human-robot collaboration—setting a new standard for precision, safety, and ease of use in smart manufacturing.